How MeiXin Brush Machinery Solves Production Challenges.

In the modern manufacturing landscape, efficiency, precision, and reliability are crucial for success. Companies producing brushes, combs, and related products face significant production challenges, ranging from high labor costs to inconsistent quality. This is where MeiXin Brush Machinery steps in, offering advanced solutions that streamline production, enhance quality, and reduce operational costs. In this article, we will explore how MeiXin Brush Machinery addresses these challenges and why it has become a trusted name in the industry.

Understanding Production Challenges in Brush Manufacturing

Brush manufacturing is a complex process involving multiple steps, including material preparation, bristle insertion, comb shaping, and final assembly. Each step poses unique challenges that can impact efficiency and quality.

Labor-Intensive Processes

Many traditional brush production methods rely heavily on manual labor. This can result in slower production rates, higher labor costs, and a greater likelihood of human error. Manual processes also make it difficult to scale operations without proportionally increasing workforce size.

Inconsistent Product Quality

Consistency is vital in brush manufacturing. Variations in bristle placement, comb alignment, or adhesive application can lead to defective products. Ensuring uniform quality across large batches is a persistent challenge for manufacturers.

Equipment Limitations

Older or poorly designed machinery may struggle with precision and speed, limiting production capacity. Frequent breakdowns and maintenance requirements can further disrupt workflow, causing delays and additional costs.

Material Wastage

Improper handling or inefficient use of materials often results in wastage. High-quality bristles and components are expensive, so minimizing waste is essential for maintaining profitability.

How MeiXin Brush Machinery Addresses These Challenges

MeiXin Brush Machinery offers innovative solutions designed to tackle each of these production challenges. Their machines combine advanced technology, precise engineering, and user-friendly design to improve efficiency and reliability.

Automation for Increased Efficiency

One of the core advantages of MeiXin Brush Machinery is automation. Automated machines significantly reduce the need for manual labor, allowing manufacturers to produce large quantities of brushes and combs with minimal human intervention.

- Faster Production Rates: Automated systems can operate continuously, increasing output without sacrificing quality.

- Labor Cost Reduction: Companies can allocate their workforce to higher-value tasks instead of repetitive manual processes.

- Consistency Across Batches: Automation ensures uniformity in bristle placement and comb shaping, reducing defects.

Precision Engineering for Quality Assurance

Quality is a critical factor in brush and comb manufacturing, and MeiXin Brush Machinery excels in delivering precise and reliable results.

- Accurate Bristle Insertion: Machines are designed to insert bristles consistently at the correct angle and depth.

- Uniform Comb Shaping: Advanced shaping mechanisms maintain uniformity across large production runs.

- Durability and Longevity: High-quality components ensure long-term performance with minimal maintenance.

Customization and Versatility

Every manufacturer has unique requirements, and MeiXin Brush Machinery offers flexible solutions to accommodate various production needs.

- Multiple Brush Types: Machines can handle different brush designs, from household cleaning brushes to cosmetic brushes.

- Adjustable Settings: Operators can easily modify parameters for bristle density, comb size, or material type.

- Rapid Changeovers: Quick adjustments allow manufacturers to switch between product lines without significant downtime.

Minimizing Material Wastage

Efficiency is not just about speed; it’s also about resource optimization. MeiXin Brush Machinery incorporates technology that reduces material wastage.

- Precise Material Handling: Automated feeding systems ensure accurate usage of bristles and other components.

- Reduced Errors: Consistent performance lowers the chances of defective products, conserving materials.

- Cost Savings: Less waste translates to reduced production costs and higher profitability.

Key Features of MeiXin Brush Machinery

Understanding the features of MeiXin Brush Machinery highlights why it is preferred by manufacturers worldwide.

High-Speed Production

These machines are engineered for high-speed operation, capable of producing thousands of brushes or combs per hour. High-speed production ensures manufacturers can meet large orders efficiently.

User-Friendly Operation

Despite advanced technology, MeiXin Brush Machinery is designed to be easy to operate. Intuitive controls, clear displays, and simple maintenance procedures make it accessible even for operators with limited technical experience.

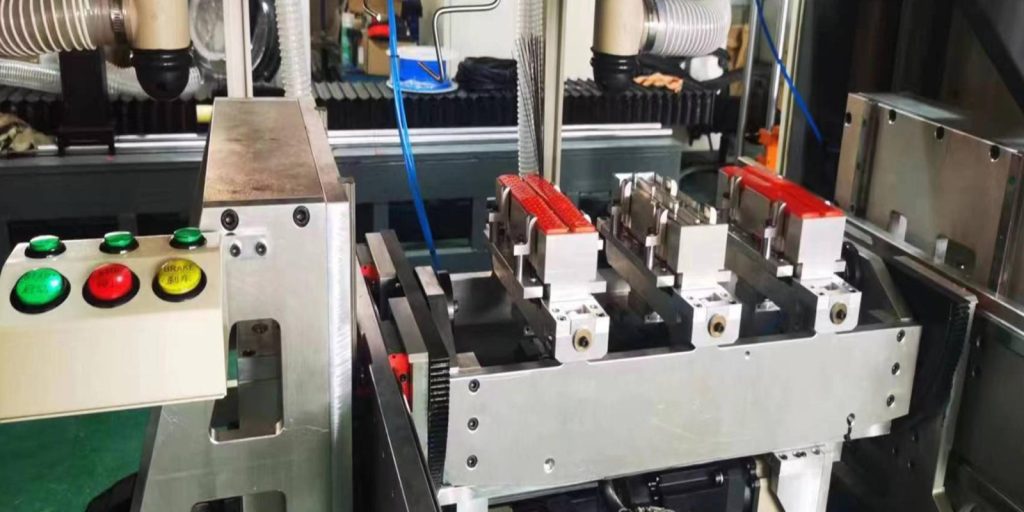

Advanced Safety Measures

Safety is a priority in any manufacturing environment. MeiXin Brush Machinery includes built-in safety mechanisms, such as emergency stop buttons, protective covers, and sensors, to prevent accidents and ensure a secure working environment.

Energy Efficiency

Modern machines from MeiXin Brush Machinery are energy-efficient, consuming less power without compromising performance. Reduced energy consumption not only lowers operational costs but also supports sustainable manufacturing practices.

Benefits of Integrating MeiXin Brush Machinery into Production

Adopting MeiXin Brush Machinery brings tangible benefits to brush manufacturers, impacting both operational efficiency and business growth.

Improved Production Capacity

By automating time-consuming processes, manufacturers can dramatically increase output. Higher production capacity enables companies to meet growing market demand and take on larger orders.

Consistent Product Quality

Precision engineering and automation ensure consistent quality across every batch, enhancing brand reputation and reducing returns or customer complaints.

Cost Reduction

Lower labor requirements, reduced material wastage, and energy-efficient operation contribute to significant cost savings. This allows manufacturers to maintain competitive pricing while improving profit margins.

Competitive Advantage

Manufacturers using MeiXin Brush Machinery can respond more quickly to market demands, introduce new products efficiently, and maintain high-quality standards, gaining an edge over competitors.

Case Studies of Success with MeiXin Brush Machinery

Several companies have reported measurable improvements after implementing MeiXin Brush Machinery in their production lines.

Example 1: Household Brush Manufacturer

A mid-sized household brush manufacturer integrated MeiXin Brush Machinery into its production line. Within six months, production output increased by 40%, defect rates dropped by 25%, and labor costs decreased significantly.

Example 2: Cosmetic Brush Company

A cosmetic brush company faced challenges in maintaining consistency across different brush types. After adopting MeiXin Brush Machinery, they achieved uniform quality, reduced material waste, and accelerated product launch timelines.

Future Innovations in Brush Machinery

MeiXin Brush Machinery continues to invest in research and development, ensuring that manufacturers benefit from the latest advancements in automation and precision engineering.

- Smart Manufacturing Integration: Future machines will incorporate IoT and AI technology for real-time monitoring and predictive maintenance.

- Eco-Friendly Solutions: Innovations will focus on sustainability, with energy-efficient designs and environmentally responsible materials.

- Enhanced Customization: Continued development will allow even greater flexibility for unique brush and comb designs.

Conclusion

In today’s competitive manufacturing environment, overcoming production challenges requires advanced, reliable, and efficient machinery. MeiXin Brush Machinery addresses key industry challenges, including labor-intensive processes, inconsistent quality, and material wastage, through automation, precision engineering, and user-friendly design. With high-speed production, energy efficiency, and versatile customization, MeiXin Brush Machinery enables manufacturers to increase output, maintain consistent quality, reduce costs, and gain a competitive edge. For any brush or comb manufacturer looking to optimize operations and enhance profitability, MeiXin Brush Machinery proves to be an indispensable partner.